A PIC BASED ELLIOTT 803 EMULATOR

I've been working on a software based emulation of the 803 for a long

time, but while over at TNMOC last

weekend we started to talk about building 803 emulators with PICs. KevinB said he had

already been thinking along these lines using a 16F877

. I've used these in the past, but I'm currently using the newer

18F series such as the 18F4520

. One advantage if these newer devices is that they can run at

twice the clock rate. Although I've only done some rough

calculations, I think an 18F device will just be fast enough to emulate

an 803.

Although a PIC has enough processing power to emulate the instruction

set of the 803 it does not have enough internal data memory to hold the

contents of the 803's core store. 803s could either be supplied

with one or two core store modules. Each module held 4096 words

on memory, with each word consisting of 39 bits of data and 1 parity

check bit. So an 803 with both store modules had 8192 * 40 bits

= 8192 * 5 bytes = 40960 bytes. I decided it would be easiest to

implement this as 5 x 8K static RAM chips.

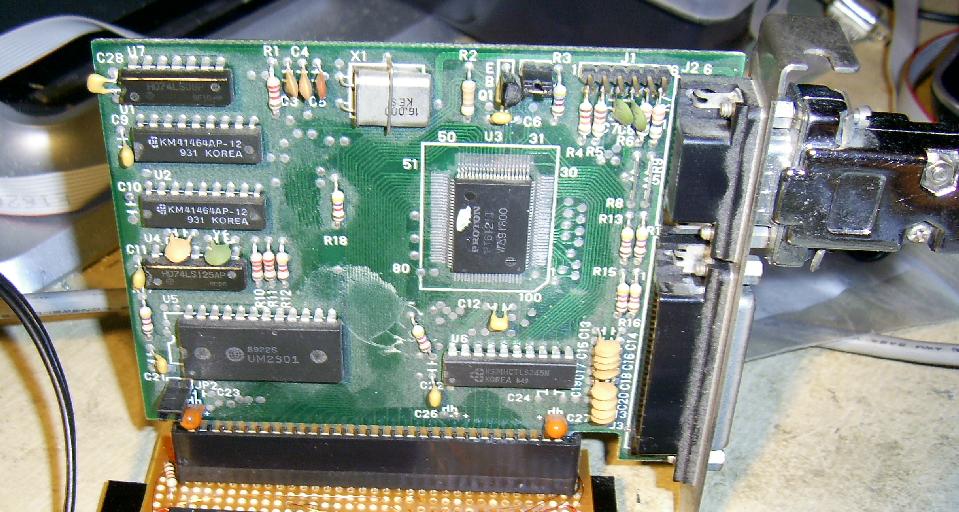

4/4/2009:

The board is as shown above. The firmware is able to read and

write words from the "core store".

5/4/2009

I've written the main fetch-execute cycle code and implemented the "00"

no-op and "40" jump instruction. The first

program was a single "jump to 1024" instruction in location 1024.

When the emulation starts at location 0 the address

LEDs can be seen counting up as the no-op instructions are fetched from

successive locations. Once the address reaches 1024 it stops and

the loud speaker emits the "dynamic stop" frequency

(3472Hz). I'm now working on the instructions from groups 0 to 3.

Well, much debugging later it's running a slightly more complex program

that involves functions "22", "55" and "40" and B-modification.

It is getting close to the point where the initial instructions will

run

which means I need to arrange a method of getting paper tape read

instructions to work. I have some I2C EEPROMS somewhere, maybe

I'll try using one of those to store a paper tape image.

8/4/2009 I've added an RS-232 interface in the space just below the

PIC. Using a very simple protocol the 803 can request characters from a

paper tape file when it executes a "71" instruction.

Also for debugging the emulator can send the op code

for each instruction is obeys up the interface to be displayed on a

PC. A sample of the output is shown below.

26 73 26 26 70 03 46--- 30 20 00 22 40 22 70 03

42--- 47--- 06 42 00 42 22 01 46 22 02 42--- 41

--- 43--- 22 44 01 41 00 41 05 42 22 30 04 05 46

22 30 04 07 42 22 30 03 05 46 22 02 05 42 22 30

20 00 01 02 03 04 05 06 07 30 05 46 22 70 03 46

--- 30 10 30 11 30 12 30 13 30 14 30 15 30 16 30

17 30 05 46 22 30 20 06 10 05 42 22 30 20 11 04

42--- 74-01 74-01 74-1c 44 30 20 12 05 42 22 30

KEY: XX octal opcode

XX--- XX is a conditional jump not

taken 74-XX Function 74 punch a

character XX

The program is part of an original 803 test program called

COM240. On the last line you can see it punched the

characters 01,01,1C which indicate that the preceding

instructions produced the wrong

result.

9/4/2009 I seem to have spent most of the last two days implementing

and debugging the Group 6 (floating point) instructions. At least

I have a known working "C" implementation to work from, otherwise it

would be much harder. I know this because I can remember how hard

it was when I was writting the "C" version ! Having a

working (virtual) 803 to use as a reference is very helpful. I've

been able to add some logging to the "C" code to dump out the values in

various registers as the instructions are executing, then I've added

similar output to the PIC code and by comparing the results I can find

the cause of any differencies. Along the way

I've discovered I have the programme sheets for a later version of X5

(Floating point test programme) than the paper tape version. So

sometime I'll have to sit and type in the "T2" version from the sheets

and create a newer version. It seems to test some potential

hardware design bugs !

I also realised that the 19200 baud serial line is much too slow to do

debugging in real time, so I've had to slug the PIC code to wait

between

instructions to give the USART time to empty the transmit buffer.

I've purchased some small switches to make up a real word generator.

11/4/2009 After a day out flying models I got back in the evening

and added some extra buffering to make the paper tape read function run

faster. Then with the addition of code to toggle a couple of the

word generator bits I attempted to load the Algol 60 compiler....

10 minutes later it was loaded and it actually compiled a quite complex

programme. However shortly after the programme started to run it

stopped in a dynamic stop, so there is something wrong somewhere.

I'll run the same programme on the software emulator and get a full

trace output to compare with the trace output from the pic

emulator. Hopefully I'll be able to see where the two traces

diverge.

12/4/2009 A day of heavy debugging ! I was able

to compare the two trace outputs, and fix a couple of error in the pic

code. One instruction was incorrectly clearing the auxillary

register when it shouldn't, and the double length divide was only

shifting the single length accumulator. So now it is sitting here

on the bench running an Algol programme :-) Off to TNMOC

tomorrow to show it off!

13/4/2009 I showed off the emulator at TNMOC, and it seemed to

impress everyone that saw it :-) There is still a bug some where

that is causing problems with floating point numbers in Algol

programmes. I'm not sure if the problem is with the floating

point instructions (group 6 functions) themselves or if it is

with some other instructions that are used when reading and

printing floating point numbers.

14/4/2009 I've spent the evening trying to compare the

trace outputs from running an Algol programme called "SIN AND COS ON

THE TELEPRINTER". I had hoped to determine exactly where the

floating point problem first shows up but it proved a little more

difficult that I expected. I really need better control of the

PIC803 so I'm going to move my attention to building a word generator.

16/4/2009 The word generator is begun! All the switches and

resistors are mounted and the 4 PIC sockets are in place. I

finally settled on a design that will use 4 PICs to monitor the 55

switches on the console/word generator. Their USARTs will be

daisy chained (Tx to Rx) to make a ring with a 5th PIC that will have a

CAM bus interface to the CPU. I've not used CAN bus before so I'm

going to have a bit of learning to do.

17/4/2009 To start with I've wired up the "N1" row of switches to one

of the PICs which I've fitted with an ICSP connection so that I can

develop to code "in place". The aim is for all four PICs to have

identical code in them, but they will configure themselves at startup

when the find which position they are in the daisy chain. Their

position in the chain will select which row tag they use

when sending button state messages. For now the

first PIC is just sensing button presses and turning on the

appropriate LED, and turning them all off when the row clear

button is pressed.

18/4/2009 After a whole day of wiring up switches and then debugging

four PICs at the same time, I finally have a word generator that can

send messages to the CPU. However the plan is to use CAN bus to

send those messages, and CAN bus is a whole new can of worms !

First off I have to rewire the CPU board because I used PORTB as the

data bus to the RAM chips, and the CAN bus signals are on RB2 and RB3.

19/4/2009 I spent the morning debugging the CPU board with the

re-assigned ports. It took longer than I expected because

somewhere along the way all my variable got moved out off the access

bank and into bank 1, which made a lot of stuff not work any more

! Oh well...... It's going again now. So now I

can start to tackle CAN bus programming. I'll take a picture of

the word generator later on this afternoon.

The large PIC on the right is a 18F4580, which has a CAN (Controller

Area Network) interface. The four smaller PICs are 18F252, and

each one monitors a group of switches (N1,N2,F1+F2,Control). The

word generator is set to 40 7:00 0 and the READ control button is

pressed. So far all I've managed to do with the CAN module is to

send a single message to itself via its loopback connection.

24/4/2009 Lots of stuff done over the last few days. Mostly

to do with getting CAN to work. The documentation makes sense

once you know how it works, but coming at it from cold it is pretty

useless. I did find some simple examples of CAN driver code

written in C which I was able to translate into some assembler.

Here is the Word generator connected up to the CPU via CAN. You

can see the small 8 pin CAN interface chips on each board and the

two 3 pin mini-DIN sockets that I've chosen as my CAN

connectors. The plugs with no wire coming from them contain the

bus termination resistors that need to be connected to each

end of the network.

All the control buttons (except Selected Stop) work, though there are a

couple of things to sort out still. 1) Releasing the manual data

button should let the program continue without having to press the

operate bar, 2) While clearing store there is a high pitch tone from

the speaker (it should be silent).

26/4/2009 I've just written a small Algol programme to try and

track down the problem with floating point numbers... Here is the

Algol programme.

FP WRDGENTEST'

BEGIN REAL A,B,C'

ELLIOTT(7,0,0,0,2,0,A)'

B:=A*100.0'

C:=A/100.0'

PRINT A,SAMELINE,B,C'

END'

The non-standard "ELLIOTT" function allows a word of 803 machine code

to be inserted

directly into the final programme, so it's sort of like the "asm"

feature found in some C compilers.

The word inserted is "70 0:20 A" which reads the word generator into

the accumulator (Function 70) and then writes the accumulator into the

variable A (Function 20).

This allowed me to set A to a known correct floating point number, and

then to multiply it by what might be 100.0 and to divide by what might

be 100.0 It is possible that the code in the compiler that

converts the string "100.0" into a floating point number is subject to

the bug, so that's why I say "what might be 100.0"

When I ran the programme on the software emulator and set the

word generator to 0.5 it printed the expected result... ".50000000

50.000000 0.0500000"

BUT.... on the PIC emulator it printed " .50000000 43.945313

.00447035" Hmmmmmm Lets try

something that doesn't need the compiler to convert strings to floating

point numbers.

FP WRDGENTEST'

BEGIN REAL A,B,C,D'

ELLIOTT(7,0,0,0,2,0,A)'

ELLIOTT(7,0,0,0,2,0,B)'

C:=A*B'

D:=A/B'

PRINT A,SAMELINE,B,C,D'

END'

Software emulator .50000000 128.00000 64.000000 .00390625

Hardware emulator .50000000 117.18750 62.500000 .00357628

The next step is to run both emulators with the instruction trace

turned on and to compare the values in the accumulator after each

instruction....

27/4/2009 The floating point bug is dead !

FP WRDGENTEST

FREE STORE= 4630- 6551

.50000000 128.00000 64.000000 .00390625

END OF PROGRAM

It was a problem with the "T" register which holds a value with only

one bit set. It indicates where each bit of the result goes as

the division proceeds. Each iteration shifts the T register one

place right, but in the PIC code I had used

rrcf TBit4,W

andlw 0x1F

movwf TBit4

rrcf TBit3,W

rrcf TBit2,W

rrcf TBit1,W

rrcf TBit0,W

it now reads

rrcf TBit4,W

andlw 0x1F

movwf TBit4

rrcf TBit3,F ; OPSE BUG ! These were ,W

rrcf TBit2,F

rrcf TBit1,F

rrcf TBit0,F

As I'm typing this the emulator is working away printing out sin and

cosine tables :-)

So now I can get on with the next part of the hardware, which is

another board with a PIC and CAN interface and an IDE interface!

I have a CompactFlash to IDE adapter board so I'll be able to store

paper tape images onto a CF card and read them into the emulator.

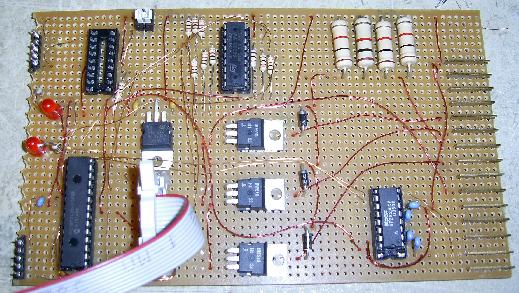

1/5/2009 The wiring on the IDE board is finished and I've started

to test it.

Top left is the 18F4580, and below that is the address decoder.

The for chips either side of the IDE connector are all 8 bit

latches. These multiplex the 16 bit IDE bus onto the 8 bits of

PortD on the PIC. The clock and output enable signals are

arranged so that the 16bit side can be read or written in one step, and

the data presented to the 8bit side in two steps.

Top right is a latch and LED drivers which will show what is going on

(Sector read, Sector Write etc).

The sockets for the 8kx8 RAM and its address latches are empty, as it s

the CAN bus driver (8 bit socket bottom right) and the RS232 driver

(bottom left).

So far I've only written some test code that shows the address decoder

and the latches are working. Now I have to start to write

the code to actually talk to a compact flash card which will be

connected to the IDE bus.

2/5/2009 I spent the morning checking all the connections to IDE

conector, and that the latches work as intended. Everything

seemed to be working OK. I found I had to add a few "nop"

instructions at critical points to give things time to settle before

clocking the latches.

Eventually (after a good afternoon of model flying) I plucked up

the courage to plug in the IDE interface and the CF card. I had

used a PCMCIA to CF card on my laptop to write a count into the first

sector of the CF card so it would be easy to tell if it was being read

correctly. I wrote some code to dump hex values to the

serial line so that I could see what was being read. The first problem

was that the data request bit in the status register never seemed to be

getting set, then I remembered to turn off the comparators that share

RD0-RD4 and it started to work. So far I've only read sector 0

(in LBA mode). I also realised I had forgotten to make

provision for driving the clock pins on the address latches for the RAM

chip, so an extra 74HC00 has been added to the board. Everything

is now wired up, so tomorrow I hope to get sectors being read into the

RAM, and then passed out to the CPU over the CAN bus.

3/5/2009 A marathon session today ! But... ***It

Works***

The programme in the IDE board is a bit crude (e.g. there is no error

checking on the IDE or CAN interfaces) but it works. The CF card

has been programmed with four tape image files simply concatenated

together. The four files are the Algol tapes 1 & 2, then the

"cogs" alogol programme tape and then the "cogsData" tape.

And it all runs at the right speed. Looking at the CAN bus

signals on my 'scope while the Algol compiler is loading ,

I can see a message coming from the IDE card every 16ms.

This contains the next 8 characters from the paper tape image, so the

reader is getting 8/16ms = 500 characters a second (which is the

correct rate).

Next step is to structure the IDE/CF card's code a bit better as it

really only the code I've written to test the IDE, CAN and RAM

interfaces all glued together. I've got a design for a simple

format to use to represent tape images on the CF card. It doesn't

need a proper file system as it only needs to be able to find the start

of each paper tape image and then read the characters sequentially

until it gets to the end of the image. Also it will need to be

able to create new images from the characters punched on the virtual

tape punches on the 803.

7/6/09 Over a month since the last update! I've been working on

two things in that time. Firstly an interface for a real paper

tape reader (more on that later) and secondly a small LCD

display. I already had this wired up to a board with an 18F458 on

it. I've upgraded the PIC to an 18F4585 and added a CAN interface

so that the various devices can display messages and output etc.

The first thing I did was to get punch output to appear on the

LCD. Currently I'm working on a higher level protocol to use

between the CAN nodes. Raw CAN can transfer only up to 8 bytes in

a frame which isn't enough for some of the messages I need to

use. So I'm working on a protocol that will allow up to 64 bytes

in a message. This has prompted some major reworking of the CAN

code and the implementation of a memory heap which can be used to store

packets.

21/6/09 As promised some details on the paper tape reader. I last

used this reader about 25 years ago on the first microprocesor system

that I built. It has sat patiently on my shelves wait for the day

when I would once again want to read some old paper tapes :-)

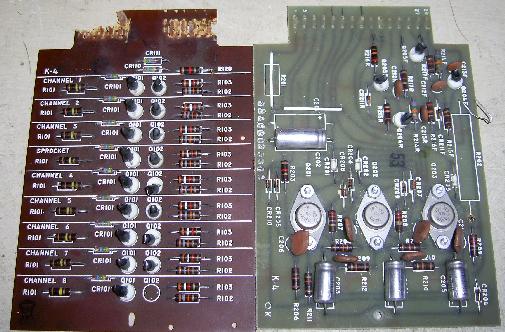

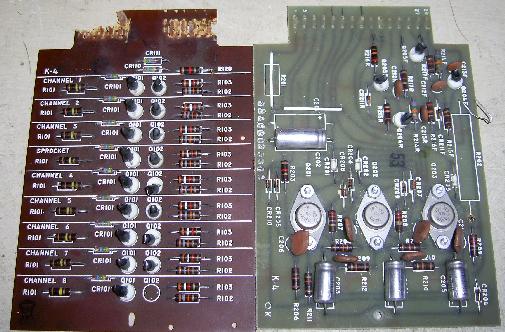

These are the two original

boards from the reader. On the left is the amplifier board which

produced logic levels of +/- 16 Volts! On the right is the

stepper motor drive board. The three power devices are

thyristors, one for each of the motor windings. The board has two

inputs, a "direction" signal (forwards/backwards) and a "step"

signal. Although this was working when I first turned the reader

on, it stopped working some time later.

These are the two original

boards from the reader. On the left is the amplifier board which

produced logic levels of +/- 16 Volts! On the right is the

stepper motor drive board. The three power devices are

thyristors, one for each of the motor windings. The board has two

inputs, a "direction" signal (forwards/backwards) and a "step"

signal. Although this was working when I first turned the reader

on, it stopped working some time later.

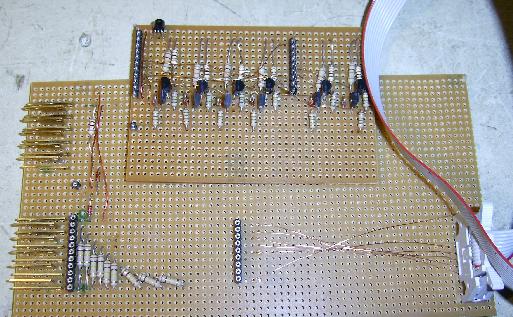

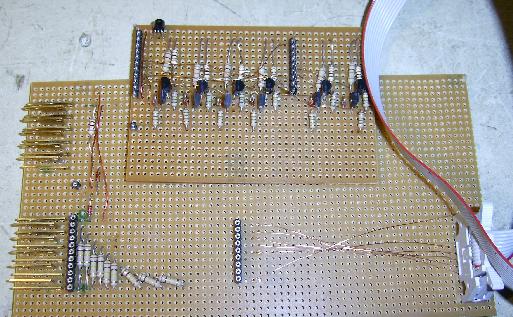

As you can see I removed the edge connector pins from the original

boards so that I could mount my replacement boards in the chasis.

Luckily the pin spacings were 0.1".

I decided to build the actuall amplifiers on a daughter

board so that I could easily change the circuit if my first design

didn't work too well. The picture shows the Mk.II amplifer board

! The circuit is similar to the original but has values optimised

for running of a +5V supply.

I decided to build the actuall amplifiers on a daughter

board so that I could easily change the circuit if my first design

didn't work too well. The picture shows the Mk.II amplifer board

! The circuit is similar to the original but has values optimised

for running of a +5V supply.

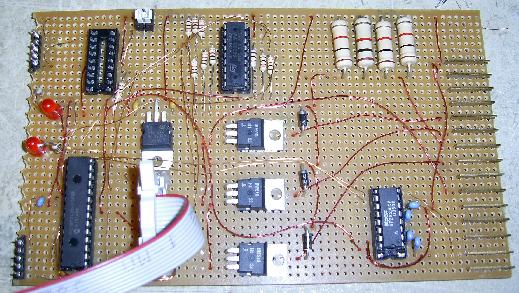

The new stepper motor driver uses three power FETs to

drive the coils. This board also contains the serial interface

for communication to the 803 emulator. The ribbon cable joins the

two boards and carries the parallel signals from the amplifier board to

the PIC on the stepper board.

The new stepper motor driver uses three power FETs to

drive the coils. This board also contains the serial interface

for communication to the 803 emulator. The ribbon cable joins the

two boards and carries the parallel signals from the amplifier board to

the PIC on the stepper board.

When a character is requested the PIC turns off the currently enabled

coil and turns on the next one to start the tape moving to the next

character. The PIC monitors the sprocket hole channel and when

the tape has moved and the next sproket hole has appeared it latches

the 5 data lines and sends the character out on the serial

interface.

24/10/09 Long time no update ! I'm about to start work on the PIC

emulator again, but this time for a different purpose. The real

803 at TNMOC occasionaly does something "odd". I'm going to try

and build a PIC 803 that can run in parrallel with the real 803 and

watch various 803 registers to detect differencies. It's quite a

challenge, but I've already goto some FIFOs to buffer the values

comming from real 803 via hardware similar to the 803 diagnositc tool.

8/12/09 I've been reworking my CANBUS networking code to support larger

messages using multiple CAN frames. The first device I've used

this new code on is a VDU.

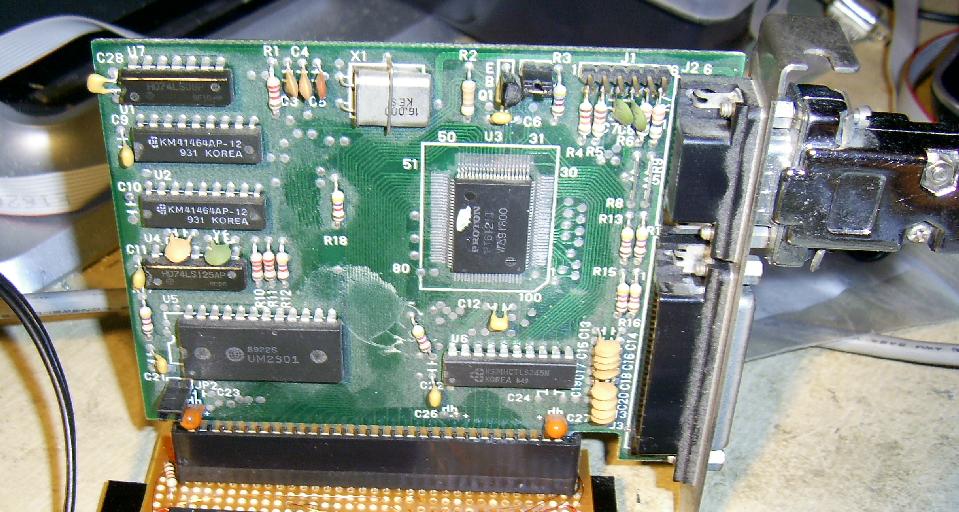

Many years ago the first PC I built used a Herculese monochrome

graphics card. The card itself has an 8 bit ISA bus interface and

I've been meaning to interface it to a PIC for a long time. So I

recovered an 8 bit ISA socket from an old 80386 mother board and wired

it up to a PIC.

The Herculese MDA clone plaaced in the 8 bit ISA socket.

The Herculese MDA clone plaaced in the 8 bit ISA socket.

As you can see the PIC board is quite simple. A couple of latches

to provide the lower 16 bits of the address bus. The top four

bits are hard wired as "B" to give the address B0000 for the cards

memory. The top four bits are ignored for i/o port

addressing. The 8 bits of the data bus are wired directly to

PORTD on PIC. The six red LEDs are wired to PORTA for debugging

purposes. The small 8 pin i.c. is the CAN BUS tranceiver.

So far the only thing that sends messages to the VDU is

the Word generator board which sends a few simple test messages to the

VDU.

So far the only thing that sends messages to the VDU is

the Word generator board which sends a few simple test messages to the

VDU.

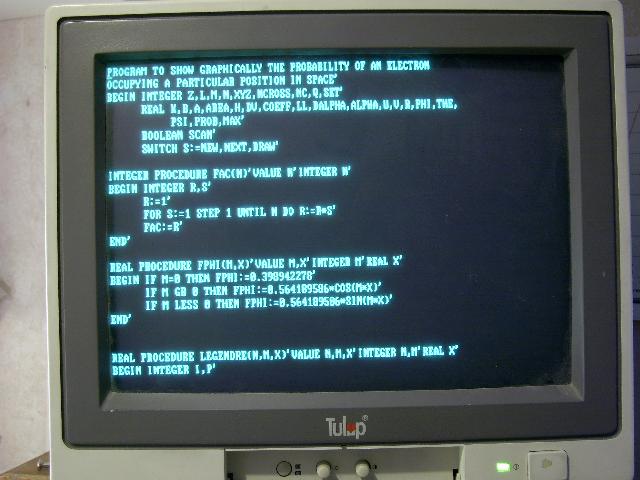

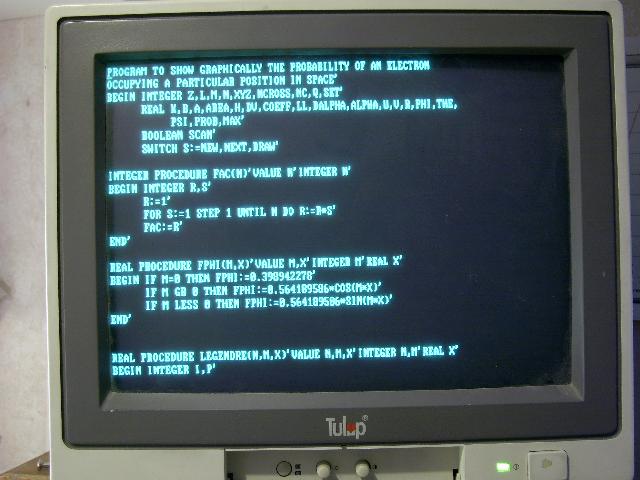

13/12/09: Here is a better picture of the VDU

display. It's now able to act as the teleprinter for the PIC803

emulator. The picture shows the output from a copy

programme. The input was an ALGOL 60 programme tape.

13/12/09: Here is a better picture of the VDU

display. It's now able to act as the teleprinter for the PIC803

emulator. The picture shows the output from a copy

programme. The input was an ALGOL 60 programme tape.

I've also been woring on the TapeStore code. (TapeStore is the new name

for the IDE board) I can now enter an offset on the numberic

keypad and the virtual tape reader will start reading from that adderss

on the Compact Flash card. The next step is to implement an index

or directory so the wanted file can be easily selected.

These are the two original

boards from the reader. On the left is the amplifier board which

produced logic levels of +/- 16 Volts! On the right is the

stepper motor drive board. The three power devices are

thyristors, one for each of the motor windings. The board has two

inputs, a "direction" signal (forwards/backwards) and a "step"

signal. Although this was working when I first turned the reader

on, it stopped working some time later.

These are the two original

boards from the reader. On the left is the amplifier board which

produced logic levels of +/- 16 Volts! On the right is the

stepper motor drive board. The three power devices are

thyristors, one for each of the motor windings. The board has two

inputs, a "direction" signal (forwards/backwards) and a "step"

signal. Although this was working when I first turned the reader

on, it stopped working some time later.  I decided to build the actuall amplifiers on a daughter

board so that I could easily change the circuit if my first design

didn't work too well. The picture shows the Mk.II amplifer board

! The circuit is similar to the original but has values optimised

for running of a +5V supply.

I decided to build the actuall amplifiers on a daughter

board so that I could easily change the circuit if my first design

didn't work too well. The picture shows the Mk.II amplifer board

! The circuit is similar to the original but has values optimised

for running of a +5V supply.  The new stepper motor driver uses three power FETs to

drive the coils. This board also contains the serial interface

for communication to the 803 emulator. The ribbon cable joins the

two boards and carries the parallel signals from the amplifier board to

the PIC on the stepper board.

The new stepper motor driver uses three power FETs to

drive the coils. This board also contains the serial interface

for communication to the 803 emulator. The ribbon cable joins the

two boards and carries the parallel signals from the amplifier board to

the PIC on the stepper board. The Herculese MDA clone plaaced in the 8 bit ISA socket.

The Herculese MDA clone plaaced in the 8 bit ISA socket.

So far the only thing that sends messages to the VDU is

the Word generator board which sends a few simple test messages to the

VDU.

So far the only thing that sends messages to the VDU is

the Word generator board which sends a few simple test messages to the

VDU. 13/12/09: Here is a better picture of the VDU

display. It's now able to act as the teleprinter for the PIC803

emulator. The picture shows the output from a copy

programme. The input was an ALGOL 60 programme tape.

13/12/09: Here is a better picture of the VDU

display. It's now able to act as the teleprinter for the PIC803

emulator. The picture shows the output from a copy

programme. The input was an ALGOL 60 programme tape.